Furniture Flips Escape Landfill

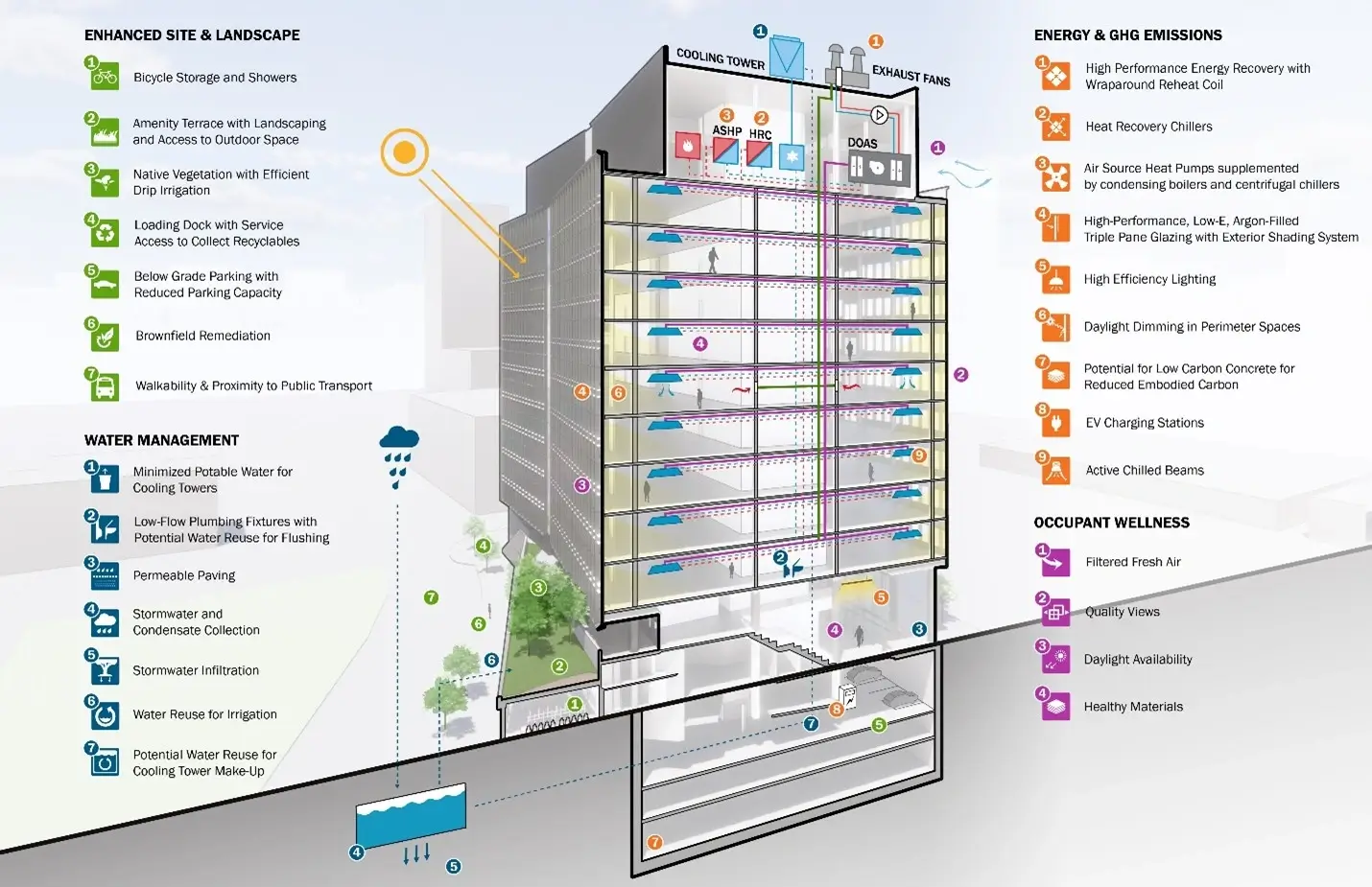

In celebration of Earth Day, we sit and contemplate what it means to be designers and where our decisions make serious impacts on the earth. The built environment generates about 40% of annual global CO2 emissions, and with that in mind, we must take accountability for our choices in every step of a project as it is realized. Even things we might not consider important can and do make a difference.

In this article we will highlight three projects where designers at ARC took the initiative to consider more ethically sourced furniture that would not only have a more neutral impact on the environment but offer a net benefit by using recycled materials that would otherwise continue to fill what seems to be an endless landfill. At ARC we are always looking at different and new approaches that can be integrated into the design process so that we are constantly being reminded about our role in the environment. We are aware that there is always room for growth and improvement and are open to new suggestions to make us better.

NEB Recycled Chairs

What?

Humanscale Smart Ocean Chair

Why/Story?

While designing a new conferencing center, the Smart Ocean chair was initially considered for its ergonomic support, all-day comfort and high-profile aesthetics, however the environmental impact that could be achieved by this one specification alone is what sold everyone on its selection for this project. The Smart Ocean chair is Living Product Certified, meeting the most rigorous sustainable manufacturing criteria to date. It is red-list free; climate, water and energy positive; and produced in a factory that uses 100% rainwater for production. Most notably, the Smart Ocean chair utilizes material from discarded ocean fishing nets that have been collected and recycled in an effort to support developing innovative solutions to prevent ocean plastic pollution.

Incorporating nearly 2 lbs. of reclaimed fishing nets into each chair, over 250 lbs. of plastic was removed from the ocean on this project.

What We Learned:

Never underestimate the power of a singular specification for your projects.

Where?:

New England Biolabs Garden Facility Expansion: Conference Center, Meeting & Huddle Rooms

Confidential Pharmaceutical Renovation

What?:

Zintra acoustic panels made from recycled PET (60% post-consumer recycled content from PET bottles / 35% pre-consumer recycled content PET chips, plus 5% PLA polylactic acid, a bio-based material).

Why/Story?

For an existing building on its campus, a leading pharmaceutical client made a decision to move away from private offices in favor of open-plan work zones. As collaboration is integral to their work, teams required enclosed rooms with good acoustics for meetings. During a recent renovation, erstwhile private offices with glazed entry walls were re-purposed as Huddle and Open Collaboration rooms with wall-mounted monitors and new furniture to support this need. ARC proposed using Zintra wall panels to dampen sound reflecting off the glass storefronts back into the room. Resembling rigid felt, Zintra comes in a variety of hues and can be cut to form patterns that provide visual interest. We devised a variety of panel configurations to offer pops of color and catch the eye of passersby. The product is red list-free (contains no chemicals of concern) and has an HPD. It contributes to building occupants’ comfort and wellbeing by abating sound.

Where?

Confidential Pharmaceutical Client: Collaborative Meeting spaces

Confidential Pharmaceutical Renovation

What?

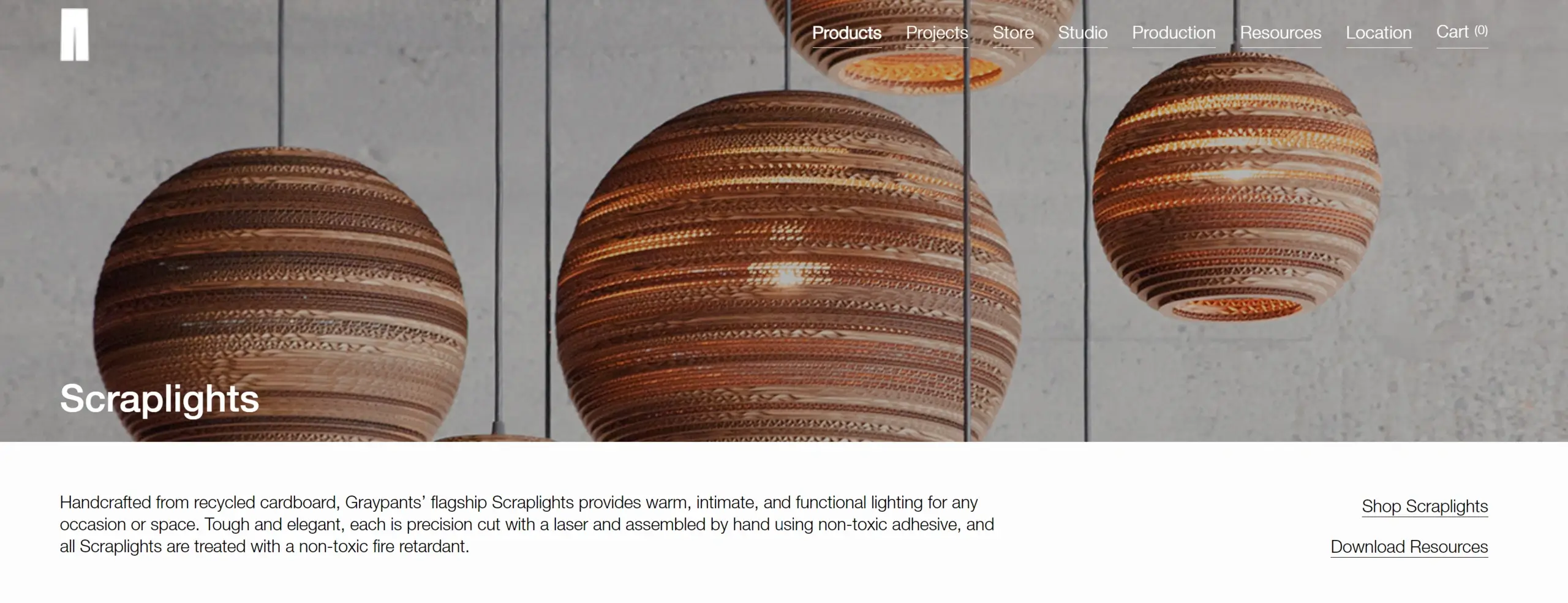

Scraplights Pendant Lighting from Graypants

Why/Story?

Commissioned to retrofit the open office interiors for a leading pharmaceutical client, ARC researched a variety of updated lighting fixtures as part of this effort. The client wanted the retrofitted spaces to provide a more engaging environment for the occupants, in contrast to the corporate feel that was previously present in these spaces. We believed the specialty lighting could contribute to this new environment and reinforce the design goals in a playful and sculptural manner, providing a more intimate quality of lighting at some of the key collaborative spaces. After reconfiguration, these areas were opened up to a greater level of natural daylighting, so the fixtures used in the collaborative areas could be scaled-down in size and quantity, so as not to compete with that enhanced natural lighting source. In addition, the fixtures needed to be LED’s, readily available, and not subject to extended lead-times, given the project schedule.

As our search progressed, many options were considered, but the pendants ultimately selected for the quality of light they would provide also had the benefit of being hand-crafted from laser-cut recycled cardboard materials, using no toxic adhesives in their assembly. The natural color and finish of the recycled cardboard material greatly contributed to the warmer lighting output and was maintained in the final fixture selection – no painted or applied finishes were needed to be added to the fixture shades.

What We Learned:

Focusing on the material content of the products we specify can lead to unique design solutions which are also mindful of our environment.

Where?

Confidential Pharmaceutical Client: Collaborative Meeting spaces and Banquette areas