Constraint Drives Innovation- Bentley Multipurpose Arena

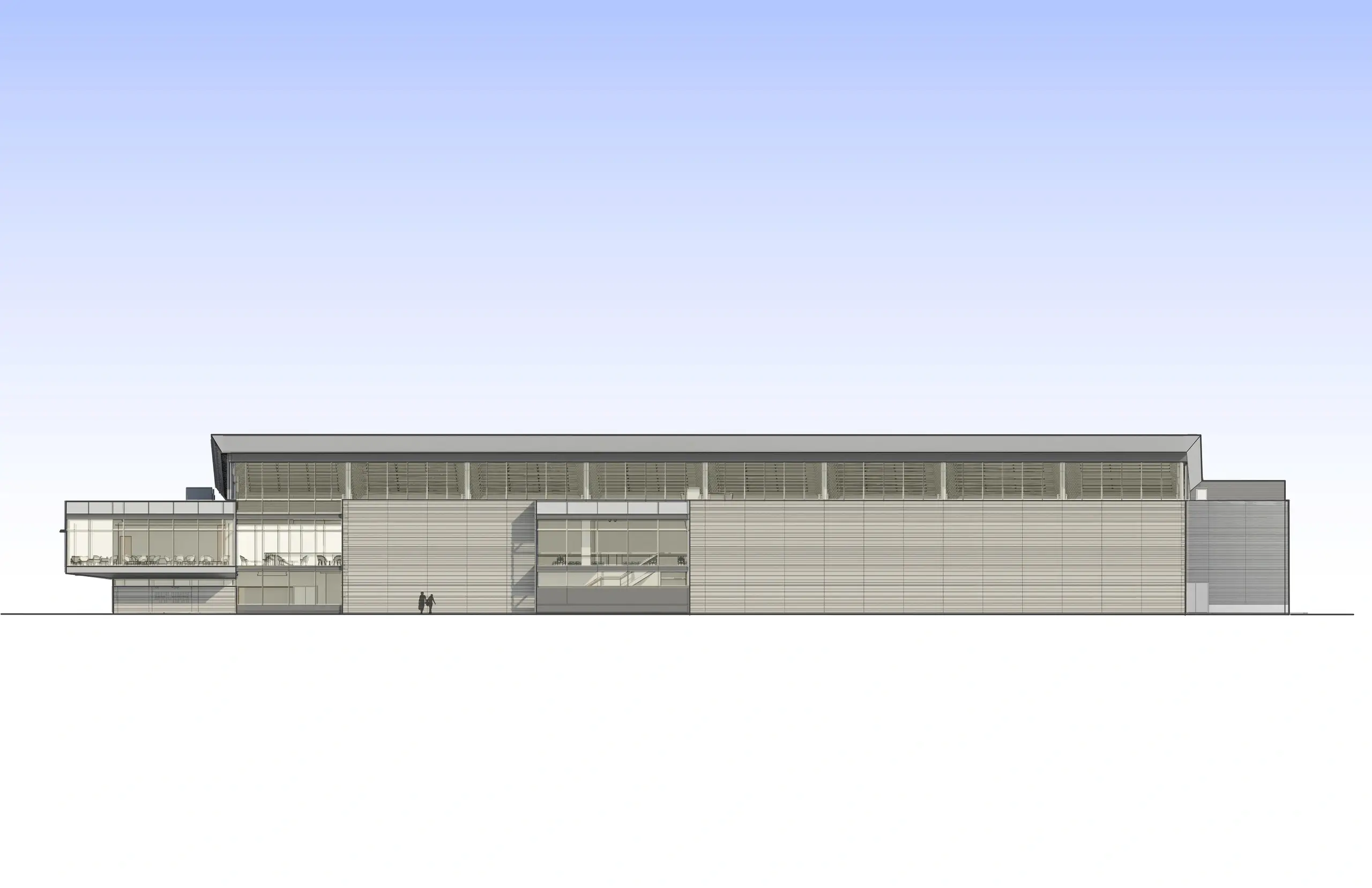

The Multipurpose Arena is a product of Bentley University’s aspirations for a transformative facility to bolster their NCAA Division I hockey team and support a dynamic, flexible event space to enhance student life for all campus constituencies. The arena hosts conferences, student clubs, career fairs, as well as comedy and concert performances.

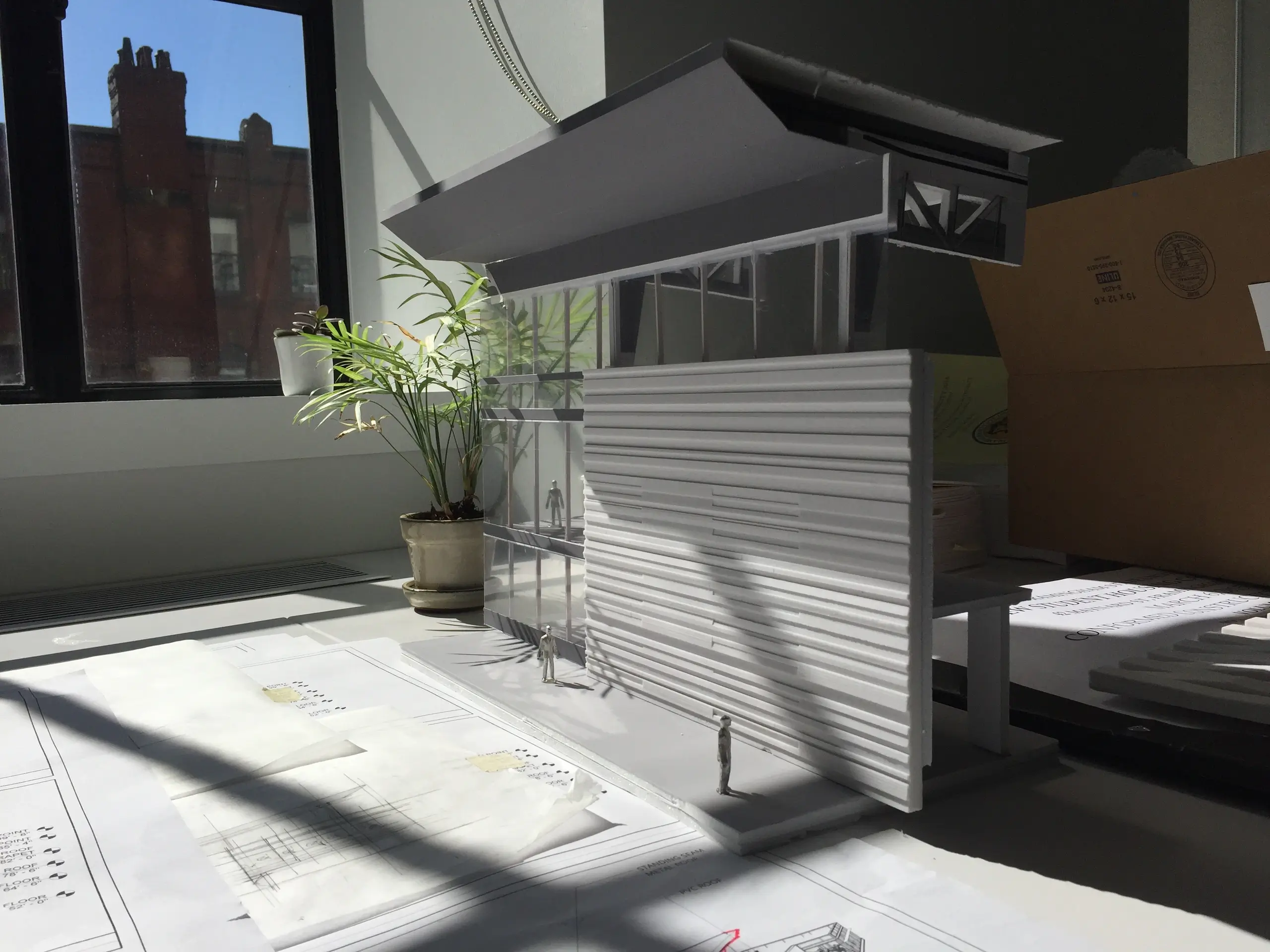

Essential to the development of the design was a deeply collaborative, integrated process with a broad range of stakeholders. Concepts were shared and debated openly, with over 60 design review meetings during a six-month period. The building reflects the strength of the partnership as the group worked collectively to refine and improve the design. From visioning sessions to construction meetings, communication and collaboration defined the process. Every partner on the project contributed to the success of the building, with fabricators becoming deeply engaged stakeholders helping to transform an inspired vision into a built reality.

A reduced construction schedule and limited budget were complicated by the University’s ambitious environmental goals. The site’s proximity to sensitive wetlands also made an ecologically responsible solution imperative.

These multiple, overlapping constraints fostered innovative solutions: A prefabricated, pre-engineered, recycled steel building system reduced construction duration, cost and embodied carbon. A modification to the conventional pre-engineered shed roof led to the creative south-facing shed roof with space for a 40,000 sf, 550 kw solar array that provides over 40% of building energy needs and helped the project become the first LEED Platinum Ice Arena in the United States.

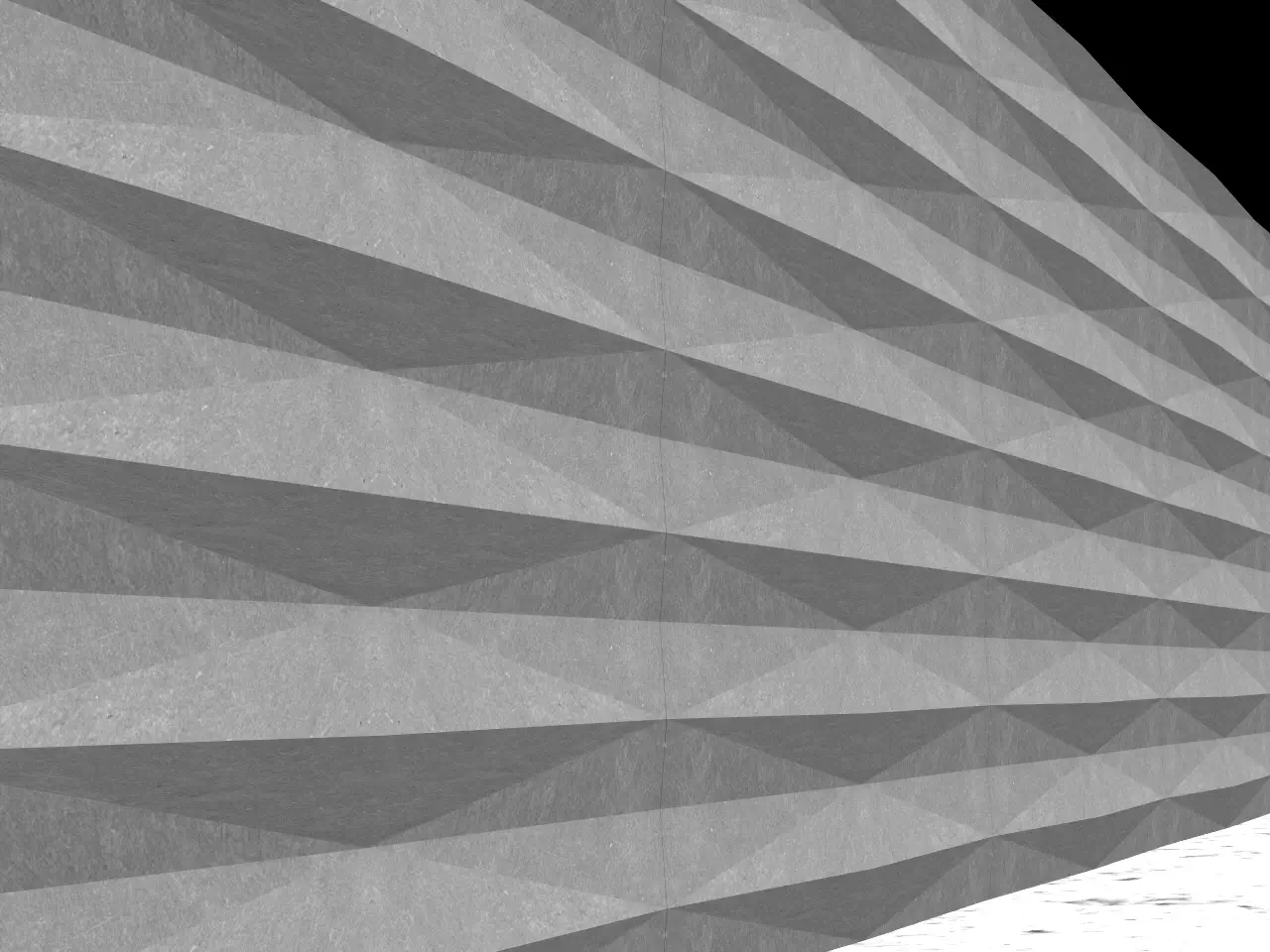

Precast Panels were the ideal solution: prefabricated with two layers of concrete sandwiched over high performance rigid insulation. The panels enhanced the performance of the building envelope, reduced construction duration, and provided a unique design opportunity. The customized concrete profile was developed with parametric modeling and 3d printing to create an active, modulated façade that is a changeable play of light and shadow depending on the season, weather, and time of day. The result is a facade that was simply fabricated and visually complex, with an angled and graduated surface that plays with light and shadow during the day.

Speed and change of direction on the ice served as the inspiration for early, abstract ideas. These concepts led to a series of facade studies that explored a wall surface that was kinetic and alluded to speed and motion.

Using 3D parametric modeling and 3D printing, ARC developed a range of facade studies that examined concepts of speed, rhythm, light, shadow and surface inflection.

As the studies evolved, ARC worked with Gate Precast in North Carolina to develop the concrete surface using different aggregates, as well as mica silica to give the facade variety, depth of color and vitality. The design of the precast surface also respected specific requirements of the mold-making process to simplify construction and maximize economy.

Further refinements of the wall design focused on coordinating the precast surface modulation to develop visual continuity and connect different facade elements across the entire building.